Your choice of stylus configuration can have a significant effect on the accuracy of the measurements you take. A few simple rules can be applied to maximize accuracy for most probing applications.

Your choice of stylus configuration can have a significant effect on the accuracy of the measurements you take. A few simple rules can be applied to maximize accuracy for most probing applications.

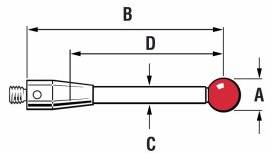

Terminology

A = ball diameter, B = overall length, C = stem diameter, D = effective working length

Effective working length (EWL)

This is measured from the centre of the ball to the point at which the stem will foul against the feature when measuring ‘normal’ to the part

Keep styli short

The more the stylus bends or deflects, the lower the accuracy. Probing with the minimum stylus length for your application is the best option.

Minimize joints

Each time you join styli and extensions, you introduce potential bending and deflection points. Wherever possible keep to the minimum number of pieces for the application.

Keep the stylus ball as large as possible

Reasons for this are: